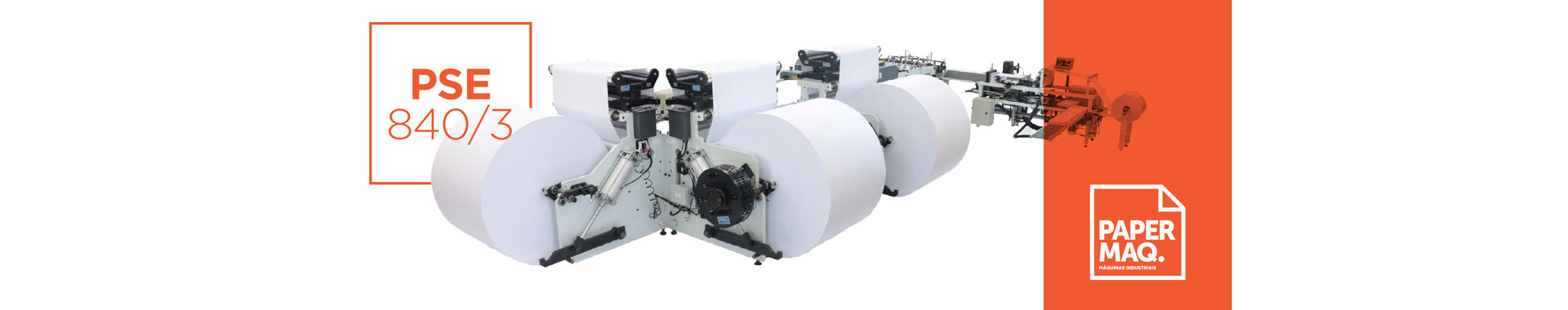

PSE-840/3 AUTOMATIC CUTTING AND PACKING MACHINE

COMPOSITION

- Three coil of paper units;

- Cutting unit;

- Output mat and vibrating table;

- Packaging system for A4 reams – (500 sheets - 75g/m²).

TECHNICAL CHARACTERISTICS OF THE CUTTING SYSTEM

COIL OF PAPER UNIT

- Three coil of paper unit;

- Coil feeder with pneumatic arms;

- Constant paper tension through load cell with microprocessed automatic control;

- Automatic marking device;

- Inverter bar on two unwinders.

- Pneumatic brake with digital controller;

- Produces 12 reams of 500 sheets in less than 60 seconds.

CUTTING UNIT

- Scissors cutting system with knife and counter-knife;

- Does not produce burrs on cut sheet;

- Static eliminator set consisting of 3 bars;

- Four rotary cutting discs for lateral reflow removal and coil opening 840mm to 210mm;

- Cut sheets A3 - A4 - A5 - Craft 2 - Craft 9 -Letter.

OUTBOARD AND VIBRATING TABLE

- Paper conveyor belt with constant segment;

- Dispensing wheels for scale formation;

- Electro-pneumatic system for ream separation;

- Four-ream forming vibrating table simultaneously;

- Automatic ream removal system for conveyor belt.

TECHNICAL DATA S

- Maximum paper width: 850 mm;

- Maximum coil diameter: 1200 mm;

- Grammage: 50 a 120g/m²;

- Various types of substrates;

- Main drive with AC motor with 10 CV;

- Pneumatic supply with pressure of 6,0 kgf;

- Digital counter with inductive sensor;

- Electronic protection system;

- Maximum speed: 150 m/minute;

- General control system via PLC.

TECHNICAL CHARACTERISTICS OF THE PACKAGING SYSTEM FOR RESTROOMS A4 - 500 SHEETS

SYSTEM PACHAGING

- Automatic ream feeding system (500 sheets - 75g/m²);

- Packing speed: 5 seconds / ream;

- Glue through applicator nozzle, with electro-pneumatic drive and tank for 4.5kg of glue;

- Uncoiling and cutting the cover, by knife and counter-knife controlled by optical sensor on the mark in the register;

- Folding and packaging, with three fold stages, driven by electro-pneumatic control;

- Aluminum frame construction and anti-corrosion treatment parts;

- 12 sensors for controlling and confirming commands.

TECHNICAL DATA

- Three-phase power supply;

- Max. Consumption 10 amp;

- Pneumatic power supply 6kgf;

- Maximum coil diameter cover 600mm;

- Maximum coil width layer 385mm;

- Recommended grammage of sheets 75g/m²;

- Adhesive application temperature 160°C a 180°C;

- General control system via PLC.

OPCIONAL

- Configuration with one or two uncoiler units;

MACHINE DIMENSIONS:

- Height: 1,5m;

- Length: 8m;

- Width: 4.2m;

- Weight: ~ 6800kg.